Ultrasonic transducers are widely used. According to the application industry, it is divided into industry, agriculture, transportation, life, medical treatment, military. According to the functions of the realization, it is divided into ultrasonic processing, ultrasonic cleaning, ultrasonic detection, detection, monitoring, telemetry, remote control and soon.; Depending on the working environment, it is classified as liquid, gas, organism, etc.; According to nature, it is divided into power ultrasound, ultrasonic detection, ultrasonic imaging and so on.

Ultrasonic motor

The ultrasonic motor takes the stator as the transducer, makes use of the inverse piezoelectric effect of the piezoelectric crystal to make the motor stator vibrate at the ultrasonic frequency, and then relies on the friction between the stator and the rotor to transfer energy and drive the rotor to rotate. Small volume, large torque, high resolution, simple structure, direct drive, no brake mechanism, no bearing mechanism, these advantages are conducive to miniaturization of the device. It is widely used in optical instruments, lasers, semiconductor microelectronic processes, precision machinery and instruments, robotics, medicine and biological engineering and other fields.

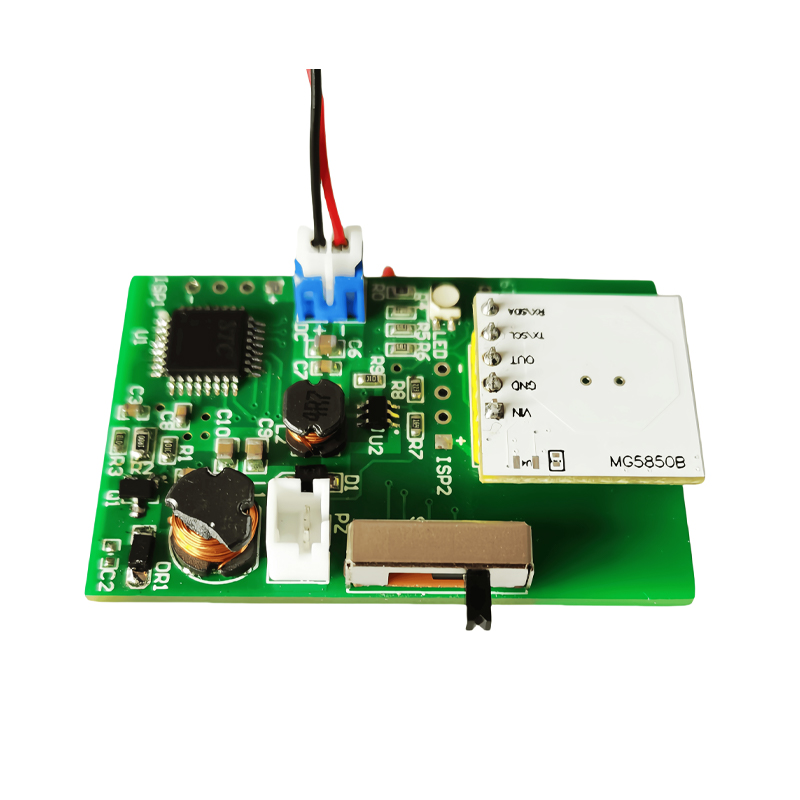

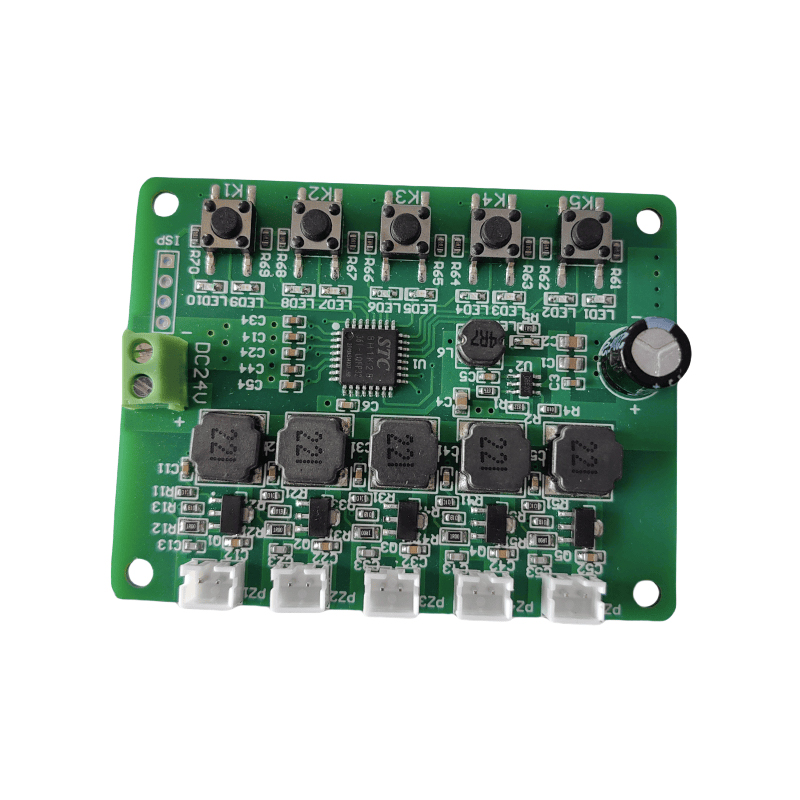

Piezoelectric ceramic transformer

The piezoelectric ceramic transformer uses the piezoelectric effect of polarized piezoelectric body to achieve voltage output. The input part is driven by sinusoidal voltage signal and vibrates through the inverse piezoelectric effect. The vibration wave is mechanically coupled to the output part through the input and output parts, and the output part generates charge through the positive piezoelectric effect to realize the electric energy of the piezoelectric body. – mechanical energy – electrical energy two conversion, to obtain the piezoelectric transformer resonant frequency at the highest output voltage. Compared with the electromagnetic transformer, this transformer has the advantages of small size, light weight, high power density, high efficiency, breakdown resistance, high temperature resistance, not afraid of combustion, no electromagnetic interference and electromagnetic noise, and simple structure, easy to produce, easy to mass production. In some areas, it has become an ideal replacement for electromagnetic transformers. This type of transformer is used for switching converters, notebook computers, neon light drivers, etc.

Ultrasonic machining

Fine abrasives and tools, together with a certain static pressure applied to the workpiece, can be machined to the same shape as the tool. During processing, the transducer needs to produce amplitudes of 15-40 microns at frequencies of 15-40Hz. Ultrasonic tools make the abrasive on the workpiece surface continuously impact with considerable impact force, destroy the ultrasonic radiation part, break the material, and achieve the purpose of removing the material. Ultrasonic processing is mainly used for the processing of precious stones, jade, marble, agate, hard alloy and other brittle materials, as well as the processing of special-shaped holes, fine deep holes. In addition, the addition of vibration in the common tool, can also improve accuracy and efficiency.

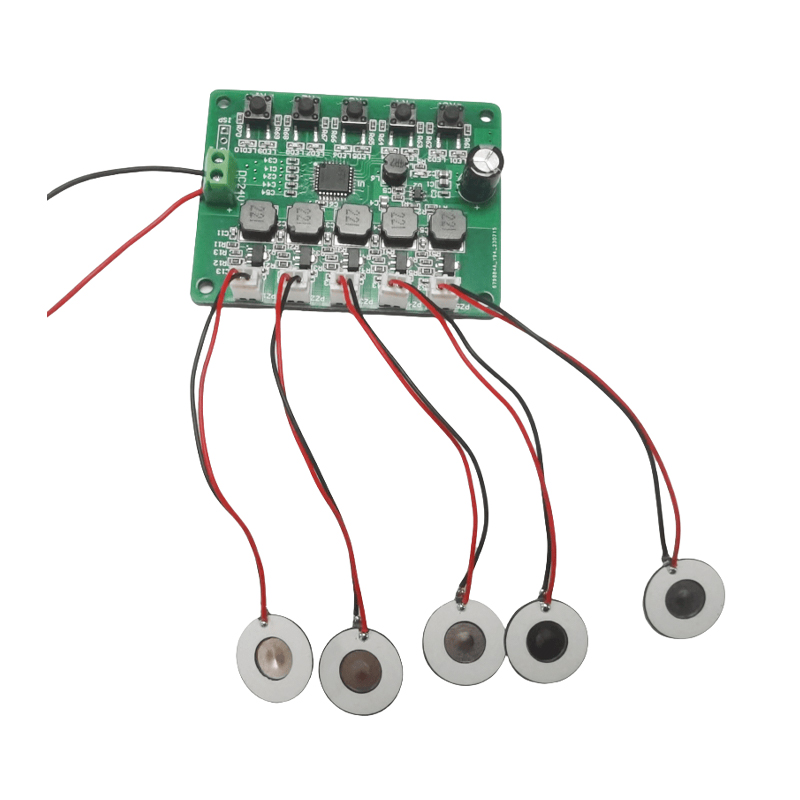

Ultrasonic cleaning

Its mechanism is to use the physical effects such as cavitation, radiation pressure and sound flow when the ultrasonic wave spreads in the cleaning liquid to remove the machinery generated by dirt on the cleaning parts, and at the same time to promote the chemical reaction between the cleaning liquid and dirt, so as to achieve the purpose of cleaning the object. The frequency used can be selected from 10 to 500 kHz, usually 20 to 50 kHz, depending on the size and purpose of the cleaning object. As the frequency increases, Langevin vibrators, longitudinal vibrators, thickness vibrators, etc.It can be used. On the miniaturization side, there are also radial and bending vibrations using disk vibrators. It has been widely used in a variety of industrial, agricultural, household equipment, electronics, automotive, rubber, printing, aircraft, food, hospital and medical research.

Ultrasonic weight loss

Using cavitation effect and micro-mechanical vibration, the excess fat cells under the epidermis of the human body can be crushed, emulsified and discharged to achieve the purpose of weight loss and shape. This is a new technology developed internationally in the 1990s. Zocchi, from Italy, was the first to apply ultrasonic degrees to beds, and was successful in pioneering plastic surgery. Ultrasonic defating technology is developing rapidly at home and abroad.

Blood pressure monitor

When the blood vessel is compressed by the balloon, the pressure applied is higher than the vasodilation pressure, so the pressure of the blood vessel cannot be felt. As the balloon is gradually deflated, the pressure on the blood vessels decreases to a certain point. When the pressure between the two reaches equilibrium, the pressure in the blood vessels can be felt. This pressure is the systolic pressure of the heart. An indicator signal is sent through an amplifier to give a blood pressure value. Because electronic sphygmomanometer cancels the stethoscope, it can reduce the labor intensity of the medical staff.

Ultrasonic welding

There are two types of ultrasonic welding: ultrasonic metal welding and ultrasonic plastic welding. Among them, ultrasonic plastic welding technology has been widely used. It uses the ultrasonic vibration generated by the transducer to transfer the ultrasonic vibration energy to the welding area through the upper welding parts. Due to the large acoustic resistance in the welding area, that is, the joint of two weldments, local high temperature will be generated to melt the plastic, and the welding work will be completed under the action of contact pressure. Ultrasonic plastic welding can facilitate the welding of parts that cannot be welded by other welding methods. In addition, it also saves the expensive mold cost of plastic products, shortens the processing time, improves production efficiency, and is economical, fast and reliable.

Ultrasonic breeding

The germination rate of seeds can be increased, mildew rate can be reduced, seed growth can be promoted and the growth rate of plants can be improved by irradiation of seeds with appropriate frequency and intensity of ultrasonic wave. It is known that ultrasound can increase the rate of seed growth in some plants by two to three times.

English

English 中文简体

中文简体